| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | Joiner |

| Model Number : | As request |

| Certification : | ISO9001 |

| Price : | USD10 |

| Supply Ability : | 5000piece/year |

| Delivery Time : | 30-60 days |

| Payment Terms : | T/T ,L/C |

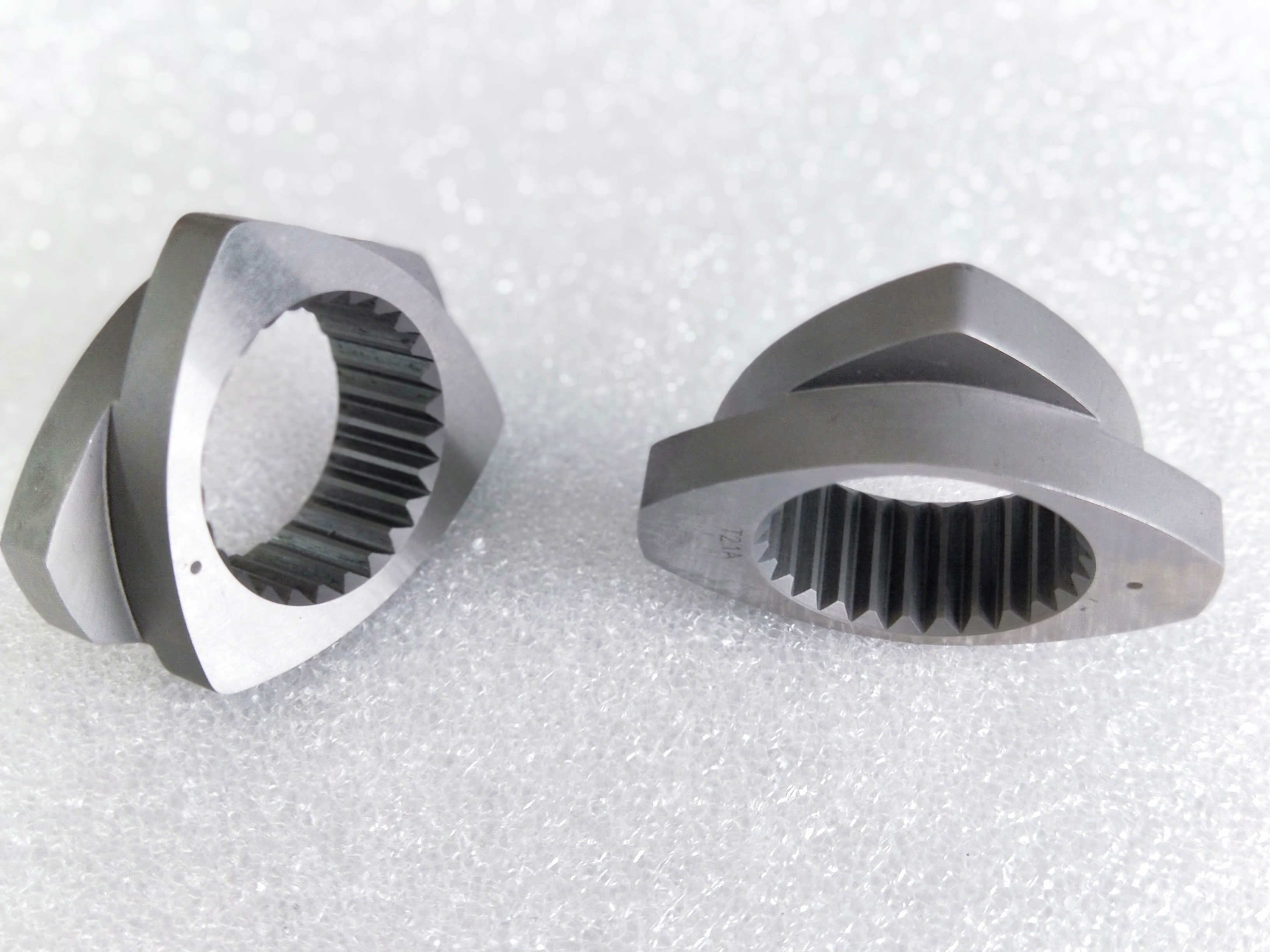

Triple Flighted To Double Flighted Transition Screw Elements / Kneading Block Of 2 Layers For Connecting

| Screw Design | Double-Screw |  |

| Hardness | 58-60HRC | |

| Brand Name | Jioner | |

| Surface Treatment | Sand blast | |

| Materials | 6542/1.2379/WR2/WR5/WR14 etc. | |

| Place of Origin | Sichuan, China | |

| Warranty | 6 months | |

| Screw Range | Φ 15.6 - Φ 400mm | |

Spline | Involute inner spline | |

2. Screw Elements Materials for Choice:

3. Process of making

4. Raw material guarantee

The company has been cooperating with domestic and foreign

first-line brand material suppliers for a long time, and has a

strict quality control and performs regular audits and inspection

of the factory (elemental analysis, metallographic analysis,

ultrasonic flaw detection, etc.) to ensure a 100% qualified status.

5. Heat treatment

Heat treatment is very important in the screw production process. In order to ensure the quality of products, Joiner has purchased professional heat treatment equipment to produce, so that we can control the construction process by ourselves. In China, we are the only company that does heat treatment by ourselves, and the heat treatment of screw components made by Nanjing factory is processed by outsiders, so the quality of products can not be completely guarantee.

6. Why choose us?

7. Packing Details:

According to your order quantities and products sizes to choose wooden boxes or cartons to pack:

8. Testing Reports for Our customer

We will send Inspection reports for every our customer.

1).General Dimension Inspection Report

2). Material certificate for customer.

|